tSM Workforce Management

The tSM Workforce Management (WFM) module is a solution for planning and coordinating fieldwork across technicians, contractors, and other resources. While it is especially well suited for telecommunications operators (managing network installations, repairs, and service orders), the module can be adapted to any industry where scheduling, routing, and resource optimization are crucial. It fully integrates with other tSM modules—such as Ticketing, Inventory, and CRM—and leverages the same low-code framework for configuring processes and forms.

1. Module Overview

1.1 Purpose and Scope

- Streamlined Field Operations: Automate the creation and assignment of tasks that require on-site intervention (e.g., installations, network repairs, upgrades).

- Optimal Scheduling: Use an advanced optimization engine to schedule tasks based on cost, distance, technician skills, and availability.

- Mobile-First Execution: Equip field technicians with a mobile interface to track daily tasks, view maps/routes, update progress, and record materials used.

- Integrated Approach: Seamlessly link tasks to Ticketing, Provisioning, or other external systems that generate work orders.

1.2 Key Features

- Work Request Catalog: Define the types of field tasks (e.g., “Install Fiber Router,” “Perform Repair on Overhead Line”), each with planning attributes (skills, duration, constraints).

- Skills Catalog: Match the skill requirements of each task to technicians or work groups that possess those abilities.

- Address and Zone Management: Handle basic GIS functionality; track addresses, territories, and zones.

- Automated Scheduling (OptaPlanner): Optimize routes, resource usage, and time windows (Vehicle Routing Problem with Time Windows).

- Dispatch and Monitoring: Give dispatchers real-time views of schedules, technicians’ locations, and on-the-fly reassignments.

- Mobile Application: Allow technicians to see tasks, mark progress, capture photos, manage material usage, and finalize work with customer signatures.

- Integration with Inventory: Reference network elements, devices, or services from the Inventory module; perform remote diagnostics or service changes on demand.

- Material Management: Keep track of stock levels, allocate materials to tasks, and sync movements with ERP or other back-end systems.

2. Core Functionalities

2.1 Work Requests Catalog

- Catalog of Preconfigured Field Works

Administrators define a catalog of work request types (e.g., “New Fiber Drop,” “Equipment Replacement”). Each entry includes essential planning data, such as typical duration, skill requirements, and any special procedures. - Lifecycle Management

Catalog items can be versioned or retired as processes change. - Integration with External Systems

Other tSM modules—or third-party platforms—can reference these catalog items when generating field tasks or “Workforce Orders.”

2.2 Skills Catalog

- Skill Definitions

A separate catalog enumerates all possible skills relevant to work orders—“Fiber Splicing,” “Electrical Certification,” “Tower Climbing,” etc. - Resource Matching

When a new field task requires certain skills, the scheduler automatically looks for technicians or work groups that possess them.

2.3 Address Management and Zones

- Basic GIS Support

Store addresses and map them to geographical zones or territories. - Hierarchical Zones

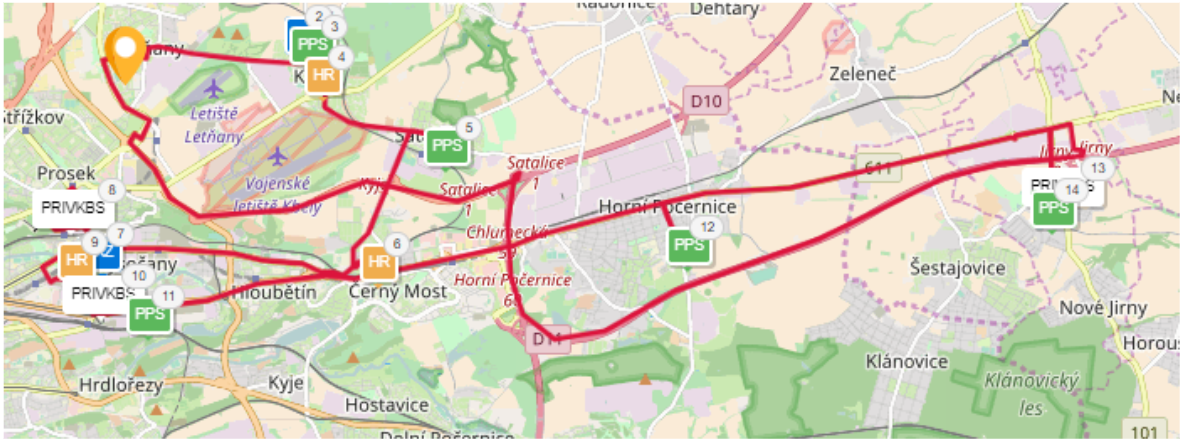

Segment territories by regions, districts, or custom areas. These zones can be assigned to specific technicians or external contractors. - Map Visualization

Use standard map tiles (e.g., OpenStreetMap) to display zones, tasks, or technician locations. Edits can be made directly in a map-based UI.

2.4 Work Resources

- Technicians, Groups, Companies

The WFM Module treats each resource as a specialized “user” or “entity” with attributes for capacity, zone coverage, skill sets, and availability. - User Profiles

Predefined or custom profiles (e.g., “Emergency On-Call,” “Standard Shift”) make it easy to switch resource parameters (e.g., working hours, cost coefficient) in case of special events or large outages.

2.5 Process and Workflow Engine

- BPMN-Based

Leverages tSM’s integrated process engine (Camunda BPMN) to define the lifecycle of a workforce order or a single field task. You can configure sequences of tasks, parallel branches, timers, notifications, or escalations. - Task Templates

Each step in the workflow can reference a predefined “task definition” (from the catalogs), specifying required skills, duration, or constraints. - Flexible Integration

Other tSM modules (e.g., Ticketing or Service Provisioning) can inject tasks into the WFM workflow. Conversely, WFM tasks can trigger updates back to those modules when completed or blocked.

2.6 Scheduling with OptaPlanner

- Constraint Solver

The engine attempts to assign tasks to resources such that all constraints (time windows, skills, location, equipment availability) are met while minimizing total cost or travel time. - Vehicle Routing Problem with Time Windows (VRP-TW)

By default, WFM uses a VRP-TW approach, but it can be adapted for more specialized scheduling scenarios. - Continuous Planning

The system can recalculate schedules in real time if new tasks arrive, existing tasks change, or resources become unavailable.

2.7 Workforce Order and Customer Appointments

- Workforce Order

A single entry point where external systems (or internal modules) request a specific job (e.g., “Set up broadband service at address X by next Friday”). The system then determines which processes and tasks are needed. - Appointment Booking

If required, the system offers available time slots to the customer. Once a slot is chosen, it’s reserved in the schedule. Dispatchers or the scheduler can later reschedule if circumstances change.

2.8 Mobile Solution (Technician Interface)

- Responsive Web / PWA

Technicians access WFM via mobile devices. They see their assigned tasks for the day, job details, and contact info. - Maps and Navigation

A built-in map shows all tasks for the day and the user’s current position. The technician can launch driving directions in a chosen navigation app. - Task Details

On starting a task, the technician can record status updates, upload photos, or note materials used. On completion, they can capture a customer’s signature or finalize required forms. - Collaboration Tools

Technicians can message dispatchers or other technicians, call external network inventory functions, or request remote support.

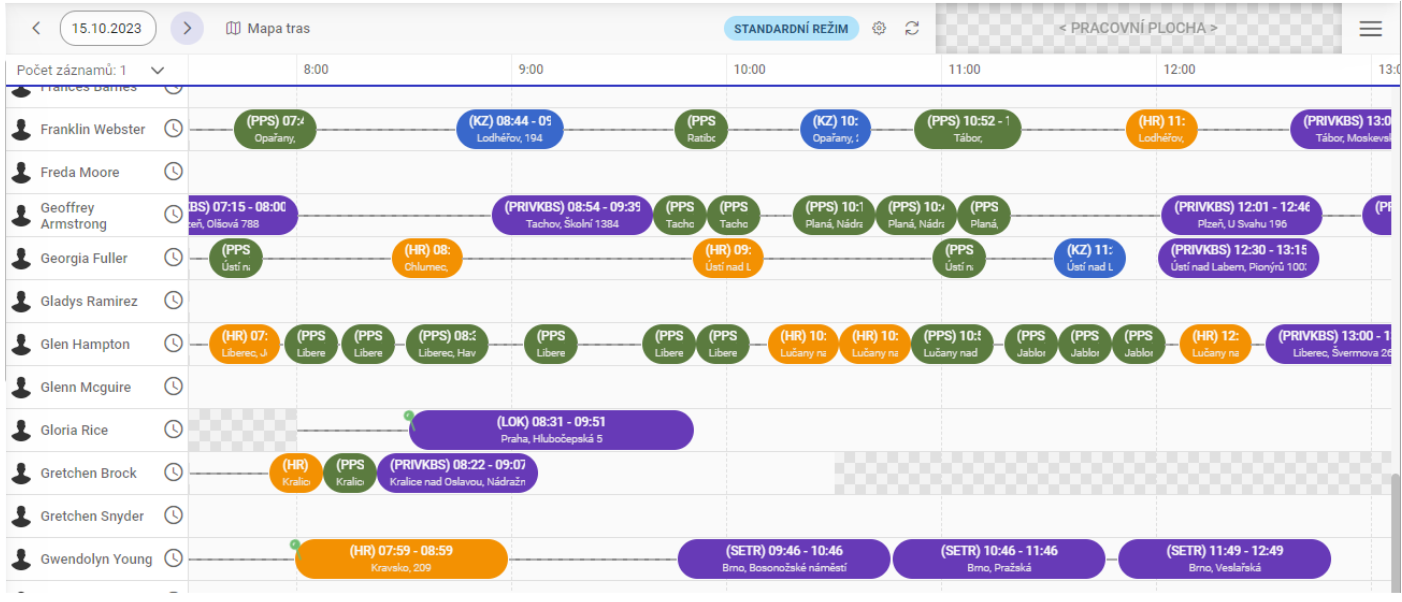

2.9 Dispatcher Tools

- Real-Time Overview

Dispatchers see a Gantt chart or map-based layout of all assigned tasks, technician statuses, and unscheduled tasks. - Interactive Scheduling

Drag-and-drop tasks to a different time slot or resource if needed. The system recalculates constraints in a “dry run” mode before committing changes. - Conflict Resolution

Update constraints on the fly (e.g., extended working hours, skill overrides) and rerun the scheduler. - Customer Notifications

Trigger automated messages or calls to customers if a task is delayed, reassigned, or canceled.

2.10 Material Management

- Stock and Inventory Sync

Sync stock data (e.g., modems, cables, spare parts) with an external ERP or the tSM Inventory module. - Material Movements

Field technicians can note which materials were used on a task, which is then reflected in stock records. - Requests and Transfers

If a technician is short on a required part, they can initiate a material order or transfer from another warehouse or colleague.

3. Integration with Other Modules

- Ticketing

- Create or update WFM tasks for incident resolution. The ticket can remain “in progress” until the field task is completed.

- A single major outage ticket can spawn multiple WFM tasks for different field teams or contractors.

- Inventory

- Reference the specific network assets (switches, lines, devices) that must be installed, repaired, or replaced.

- Technicians can call diagnostic actions from the field using the integrated UI.

- CRM / Ordering

- A new customer order (e.g., fiber installation) triggers WFM tasks if on-site work is required.

- Appointment booking data is shared with the CRM so the customer sees or confirms their scheduled visit.

- Change Management

- For tasks requiring network reconfiguration, the WFM flow can initiate or link to a change request in the Change Management module, ensuring the standard governance process.

4. Best Practices

- Refine Catalogs

- Keep your Work Requests Catalog up to date with accurate durations and skill requirements.

- Define a clear Skills Catalog to ensure the scheduling engine can correctly match tasks to technicians.

- Use Zones and Geofencing

- Divide large territories into regions to limit the scheduling complexity and reduce travel time.

- Assign resources to relevant zones to simplify or automate resource selection.

- Configure SLA and Constraints Thoughtfully

- Overly complex constraints can hamper scheduling performance. Strike a balance that meets business needs while keeping solver times manageable.

- Leverage Low-Code Workflows

- Combine BPMN processes with the WFM engine to unify notifications, escalations, or parallel tasks.

- Use the built-in form designer to adapt or extend data capture in the field.

- Optimize Scheduler Performance

- If the problem set is large (thousands of tasks), consider partitioning tasks by region, skill sets, or date ranges.

- Test different solver settings and “planner modes” (e.g., “Standard,” “Emergency”) before going live.

- Empower Dispatchers

- Provide training on how to override or fine-tune the schedule in real time.

- Encourage dispatchers to use the “dry run” mode to experiment without disrupting the active schedule.

- Track KPIs

- Monitor key metrics, such as average travel time, on-time completion, first-time fix rates, and resource utilization.

- Use these insights to refine catalogs, skill assignments, or scheduling logic.

5. Summary

The tSM Workforce Management Module offers a comprehensive platform for planning, scheduling, and executing on-site work. Drawing on advanced optimization (OptaPlanner) and an integrated BPMN workflow engine, it aligns tasks with the best-suited resource in the most cost-effective way—while enabling real-time dispatch, collaboration, and customer updates. When paired with tSM’s other modules (Ticketing, Inventory, CRM), WFM becomes an integral part of end-to-end service delivery and network operations. By centralizing data, automating scheduling, and empowering technicians with a mobile-first approach, organizations can increase efficiency, reduce operational costs, and elevate customer satisfaction.